If you’ve ever been on our website, you’ve probably noticed our patented SealTite® Band being mentioned frequently. This article is an in depth look at what it is, and how it came to be.

The Rough Start on the R&D Journey

Founder of Cutting Edge Bullets, Dan Smitchko, first set out on his journey of bullet design development in 2006. He had one goal in mind: to create a bullet that performs as well in the field as it does on the range. And to be honest, it was a rough start.

Initial testing on several iterations of different bullet designs revealed one major issue: fliers. A flier is that one shot in a consecutive string that lays way outside the other shots in the group. Fliers are caused by gasses escaping around the bullet as the bullet exits the barrel. As you can imagine, fliers are not good for match shooting OR hunting. After all, you have to have consistent, reliable groups in order to be successful at both.

Throughout the R&D process, Dan had been confiding in a select few about these issues. One of the people he had discussions with was Bruce Baer of Baer Custom Rifles. When Dan told Bruce about the flier issue, Bruce told him that you simply can’t make a solid copper bullet that doesn’t produce fliers, and this is why they are never used in competition. This is because of their inability to upset.

This one simple notion changed everything and set forth a trajectory that put our bullets on the map. See, a lead core bullet is soft. When fired, a lead core bullet “upsets” and molds to the rifling inside your barrel. This creates a perfect seal as the bullet exits, thus, no fliers. A solid copper bullet simply cannot do this.

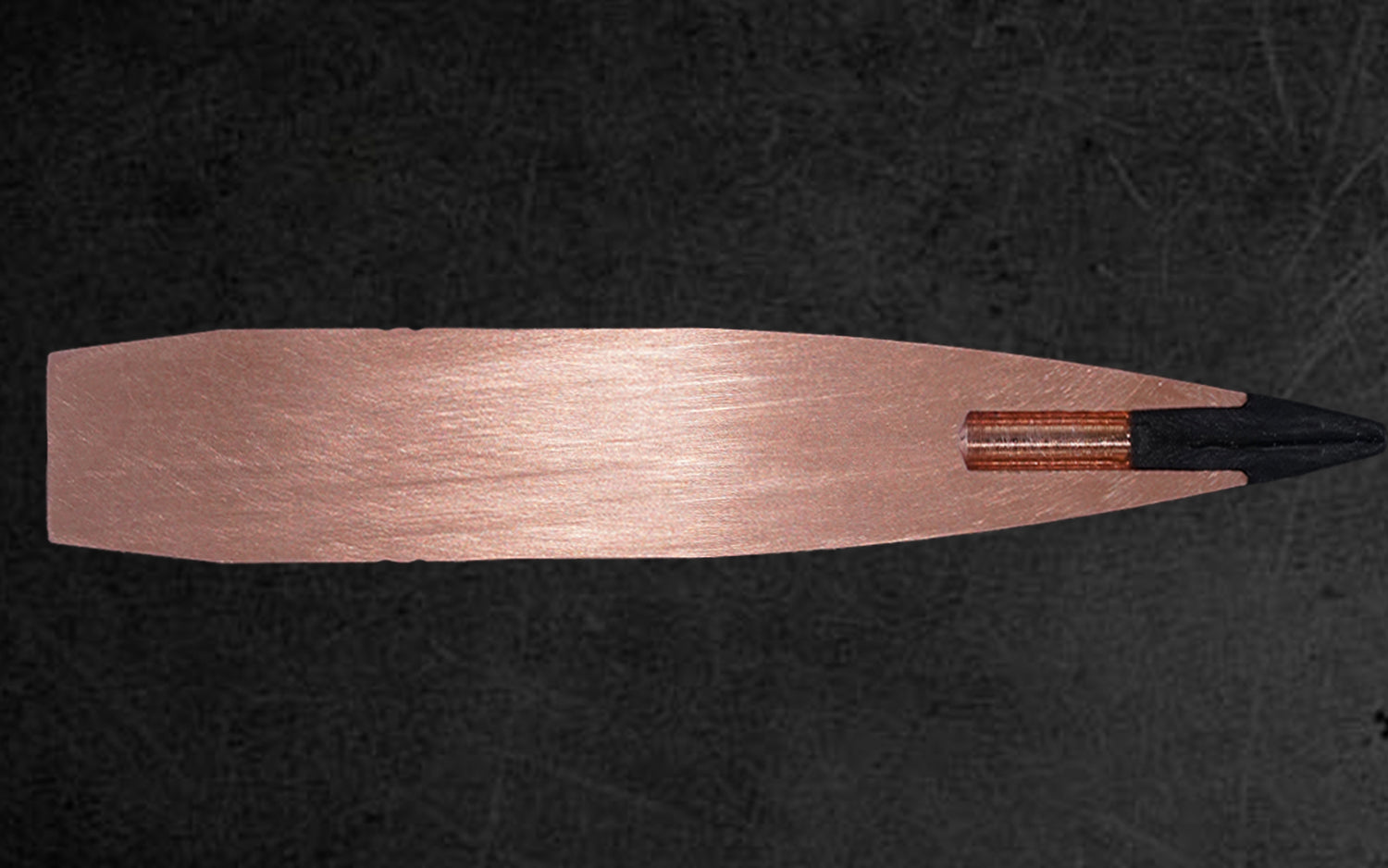

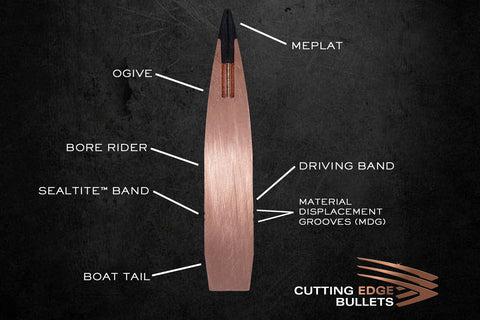

This got the wheels turning. Dan wondered if it would be possible to create a band slightly larger than caliber diameter around the copper bullet in order to replicate this sealing effect. As you can imagine, no bullet on the market had every done something like this, so initial testing of this band included hiding behind a tree while pulling the trigger. Alas, nothing was destroyed, and fliers disappeared. The SealTite® Band was born.

Worried about pressure? As you can see in the diagram above, not only did we create the band, but we put material displacement grooves in front of and behind the band to provide a place for that material to move to. This design prevents excess pressure.

Copper Fouling and Monolithics

When people hear solid copper bullets, many people immediately think of copper fouling. Copper fouling is prevalent in solid copper bullets due to the hot gasses escaping around the bullet at it exits the barrel, thus heating the copper and plating the barrel. This leads to inaccuracies when shooting and increased cleanings. This shies many people away from shooting copper bullets, but with the development of our patented SealTite® Band, copper fouling is no longer an issue. As mentioned previously, this feature creates a complete seal, thus, those hot gasses do not escape around the bullet like a traditional copper bullet. Shooters switching from another brand of monolithic bullet will notice a significant reduction in copper fouling with our bullets.

So as you can see, with the development of the SealTite® Band, it turns out that monolithics CAN be match grade after all. Need more proof? Head over to our ELR Post to see why more extreme long range champions use our bullets than any other bullet manufacturers' combined.

Thanks for reading!

As always, feel free to reach out to us at support@cuttingedgebullets.com if you have any questions or need help with selecting the right bullet.

-Samantha Smitchko

VP of Business Development