COPPER VS. LEAD BULLETS

The monolithic construction of our bullets eliminates inherent problems found with jacketed lead core bullets.

A few of the main reasons our bullets are superior to others on the market are:

- Swaged bullets may have varying jacket thickness which results in gyroscopic instability. Some match shooters invest time and resources into measuring this thickness to find a group that have a consistent jacket thickness. Our bullets eliminate this problem because the bullets are precisely machined resulting in each bullet being identical and true on its axis.

- Concentricity between the bullet body and the boat tail is much more difficult to maintain with swaged bullets versus our bullets with everything being machined perfectly true.

- Swaged bullets can also have the problem of jacket separation with some jacketed match bullets. There have been cases, especially if someone tries to shoot a swaged bullet too fast, where they separate in mid flight and disintegrate before reaching the target. Also, chances are that if you have killed enough game, you have come across a jacket in the animal without lead in it. Once separation occurs there is nothing to protect the lead and it can then pulverize into tiny pieces.

- Meplat diameters are inconsistent and ragged on Swaged hollow point bullets. Our Meplat, or nose tip diameters, are always the same perfectly round shape and flat on the end with bullet over all length precisely maintained. The hollow point is inspected to ensure it is precisely on the centerline of the bullet every time.

- Our bullets are produced from an environmentally friendly 99.5% pure copper alloy that does not contaminate the environment or the meat that you will be eating.

6. Our solid copper bullets up to and including .375 caliber are consistant every time being within .40 grains in maximum weight deviation. Bullets over .375 caliber are maintained within .8 grains maximum weight deviation. All of our bullets are concentric within .0001" and within .00015" in diameter.

THINK FAST

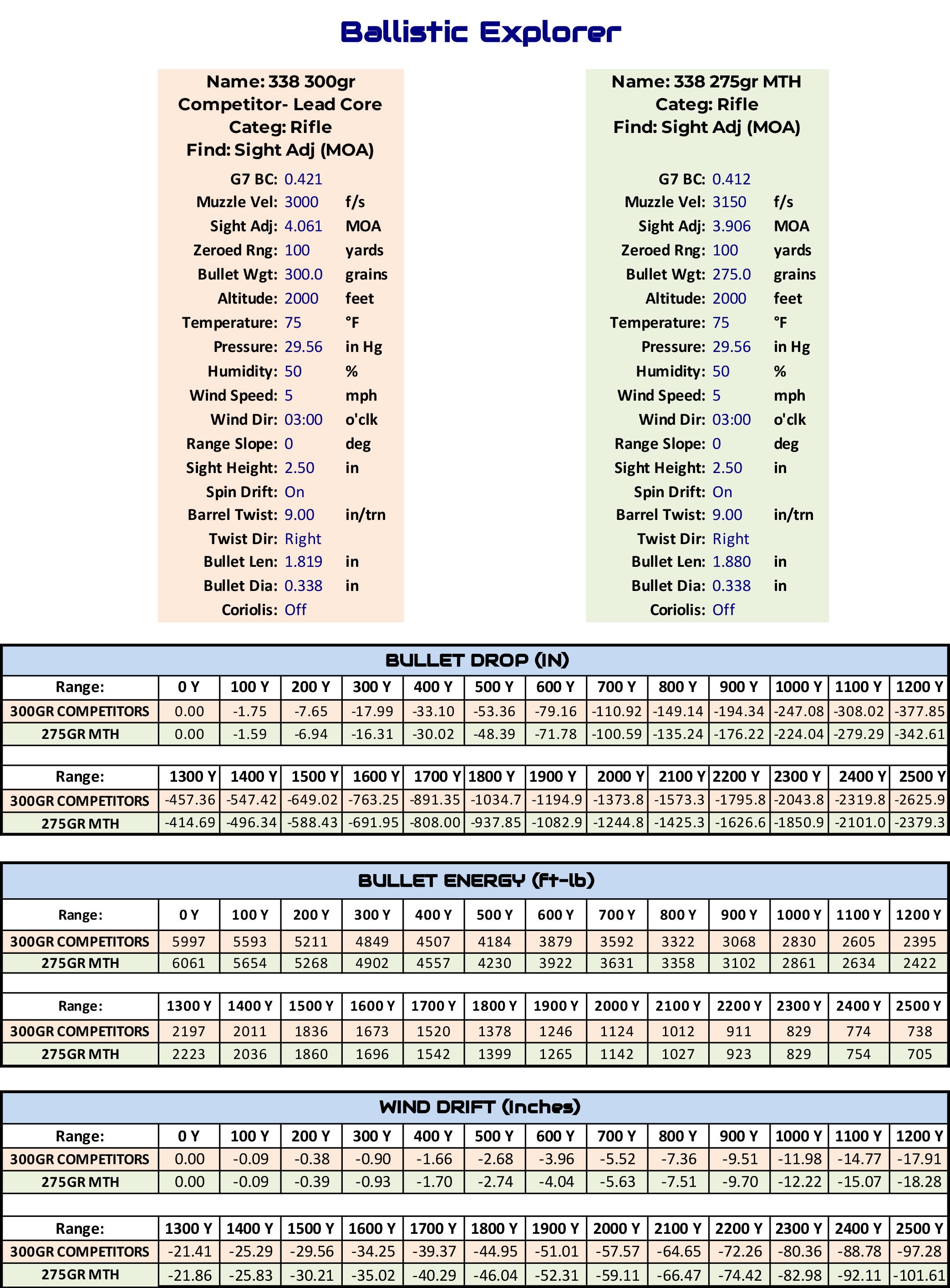

Using Solid copper bullets requires a different way of thinking than with jacketed lead core bullets. Since copper is lighter and less dense than lead, it is not practical to make very heavy bullets without making them extremely long. Very long bullets require a much faster twist barrel to stabilize them, which are not standard on factory rifles, and become unstable quicker. Thus, the use of lighter bullets requires "thinking faster" instead of heavier. A lighter bullet with a high ballistic coefficient shot at faster speeds has less drop at all ranges than heavy jacketed bullets. Energy is slightly less and wind drift is virtually the same. See graph to the right.

Most lighter bullets suffer from low ballistic coefficients and therefore are not a good alternative to heavier bullets as heavier lead core bullets tend to have a higher ballistic coefficient due to their density being greater. Our bullets are engineered to obtain maximum BC without becoming unpredictable so they are not difficult to tune. Also, just because a bullet does have a high BC it doesn't necessarily mean it is more accurate. Our bullets are designed with accuracy being of utmost importance. Not only are they extremely accurate, their terminal performance is second to none, especially at long range. Once you shoot them you will realize the advantage of going to solid copper bullets turned on a Swiss style lathe with our exclusive SealTite Band feature.